- Back

- Balancing

- Capacity

- Charging

- Connections

- Data and operations

- Land and assets

-

Insight and innovation

- Back

- Home

- Insight and innovation

- Transmission innovation

- Summer Outlook

- Winter Outlook

- Gas Ten Year Statement (GTYS)

- Gas Future Operability Planning (GFOP)

- The future of gas-fired generation

- Understanding within-day behaviour

- Identifying future drivers of change

- Changing supply patterns

- Future of gas

- Stakeholder resources

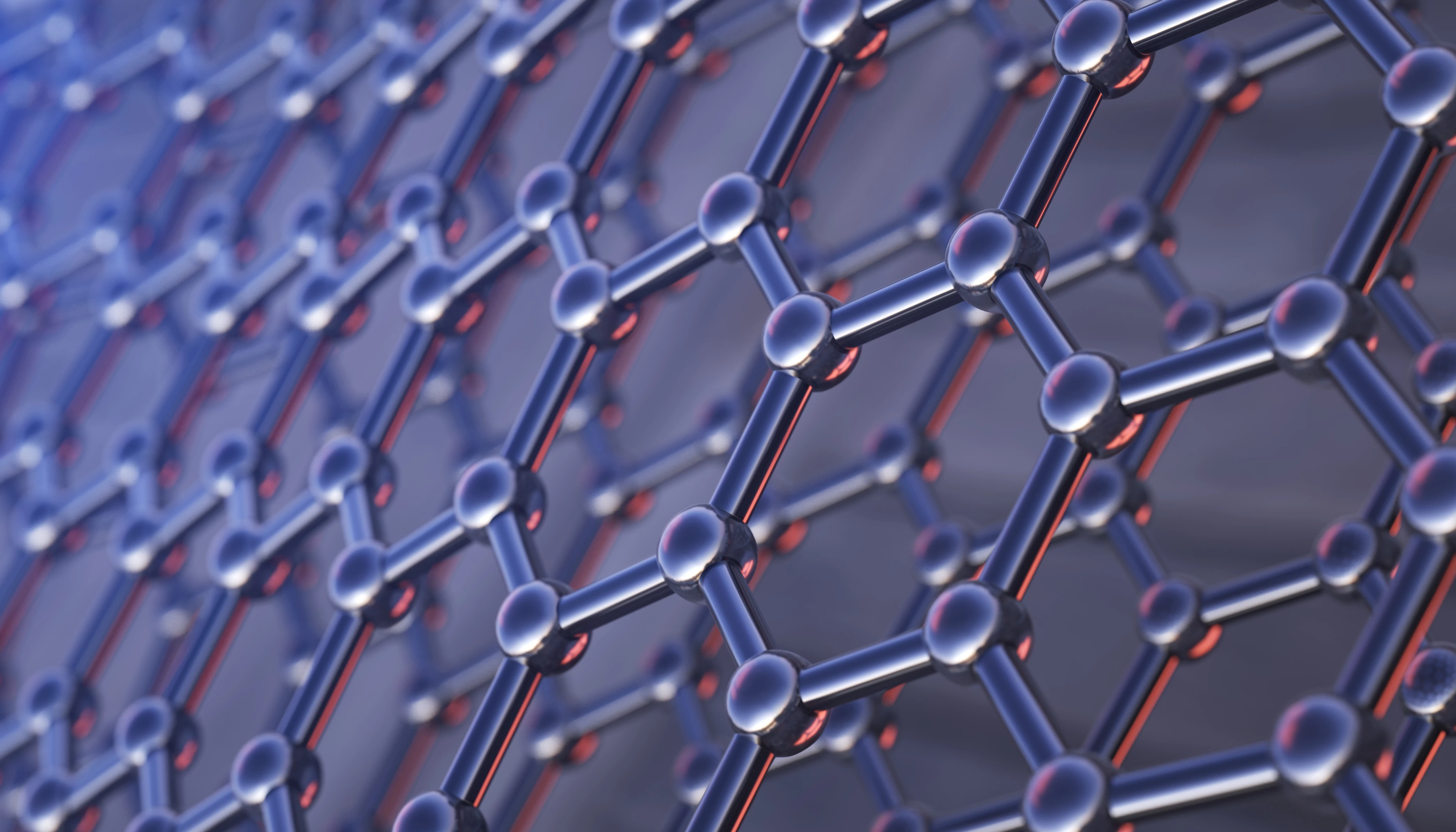

Multifunctional graphene coatings for pipeline protection

We’re running a project looking at whether we can use graphene as a protective barrier within pipelines to reduce the risk of embrittlement or as an additive to improve the performance of the paints used to protect the external surfaces from corrosion.

As we look to transition our network to carry hydrogen, we need to look at ways to mitigate the risk of hydrogen embrittlement and reduce the potential of corrosion.

Hydrogen embrittlement refers to the potential deterioration of the structural properties of solid metals due to the presence of hydrogen.

We’re running a project looking at whether we can use graphene as a protective barrier within pipelines to reduce the risk of embrittlement or as an additive to improve the performance of the paints used to protect the external surfaces from corrosion.

The graphene is produced as a by-product of microwave plasma methane pyrolysis. This is a process in which focussed microwaves directly ionise the methane gas which, upon cooling, form hydrogen gas and graphene.

This will be used as part of lab-based testing and applied to material coupons to evaluate the impact of coating design, thickness and application method.

Alongside this, the project looks to develop smart coatings that can be applied to pipes to utilise the conductive properties to detect early damage of the pipeline material before it can cause failure.

Although this will be undertaken using lab-scale samples of National Transmission System (NTS) materials, a calculation tool will be carried out to consider the process for the wider 7,500 km of NTS pipeline.

Following this initial testing, the outcomes will be used to develop a protocol for a second phase project looking at larger scale testing of NTS assets.